We often need power backup, especially in rural areas, automotive, or during campaigns. Batteries play a crucial role in these cases.

They are also essential in off-grid or hybrid solar systems. A 2000-watt, 3000-watt, and 5000-watt inverter are often used in these situations.

Most people make mistakes when sizing the batteries for these inverters.

This article will tell you how many batteries are needed for a 5000-watt inverter. To do that, we’ll give you two examples of lithium and lead-acid batteries.

Following this guide, you can also size your battery for more power. We hope that this guide will clear up many people’s misconceptions. So, stay with us and read this article carefully.

How Many Batteries Do You Need for A 5000-Watt Inverter?

Sizing the battery for an inverter is always a critical step. Most people go wrong with this, especially when picking the correct battery voltage.

For a 5000-watt inverter, you need to think carefully about what size battery you need.

Don’t worry! You only need to know about some technical factors. Generally, the most critical factors are battery voltage, capacity, C-rate, and battery type.

Why Must You Choose a Higher Voltage Battery?

We all know that P (Power) is equal to the product of V (Voltage) and I (Current), P = VI.

This means that higher voltage needs lower current, while lower voltage needs higher current. Let’s check the following example:

Residential solar power ranges typically from 250W to 450W.

For simplicity, let’s use 400W as our power. We take both 12V and 48V batteries for the comparison. Let’s check the following for more clarification.

400W/12V = 33.3A ≈ 34A, which needs 40A charge controller

400W/48V = 8.3 A ≈ 9A, which needs 10A charge controller, which is cheaper.

We can see that, using a higher voltage battery you can save a significant amount of money.

Most importantly, it is efficient and produces less heat.

| Features | Higher Voltage (48V) Batteries | Lower Voltage (12V) Batteries |

| Current Handling | Require lower currents for the same power output | Require Higher currents for the same power output |

| Component | Allow for smaller-rated charge controllers and fuses | Require larger-rated charge controllers and fuses |

| Cost | The initial cost might be higher | The initial cost is lower |

| Efficiency | Often more efficient in power transmission | May experience higher losses in power transmission |

| Scalability | Offer greater scalability for larger systems | Less scalability for larger systems |

| Safety | Lower current handling reduces the risks of overheating. | Higher currents may create heat, which poses greater safety risks. |

Two Important Factors to Consider When Sizing Your Battery

When you size your battery, consider two main facts: battery voltage and capacity. These two parameters help you determine the correct battery size. We will discuss these in brief later. Before that, let’s understand the basics of these two parameters.

Voltage is the potential difference between two points. Simply, it is the force that pushes electric charges along a conductor (wire or battery).

The most common choices for inverter batteries are 12V, 24V and 48V. When choosing the battery size, always go for higher voltage. We recommend a 48V battery because it is efficient, cheap, and safe.

On the other hand, capacity is the amount of electric charge a battery can store and deliver over a certain period.

For example, A 100Ah battery can deliver 100A in 1 hour, 20A in 5 hours, and 1A in 100 hours.

The C-rate measures how fast a battery can be charged or discharged relative to its capacity.

Every battery has a recommended C-rate. A typical lithium-ion battery has a C-rate of 1C, while a lead acid battery has only 0.2C. Let’s observe them numerically.

100Ah x 1C = 100A [Lithium-ion Battery]

100Ah x 0.2C = 20A [Lead Acid Battery]

A 100Ah lithium-ion battery should be charged and discharged at a maximum of 100A. On the other hand, a 100Ah lead-acid battery shows 20A, which is significantly less current. You can still pull 100A from a lead-acid battery, but the battery won’t last very long; heat will be generated and degrade faster. You also wouldn’t be able to extract 100Ah because a lot of energy is lost in heat.

Lithium Battery: How many batteries are needed for a 5000-watt inverter?

A lithium-ion battery is a rechargeable battery. It uses lithium ions as the primary means of energy transfer.

It offers high energy density. In addition, Li-ion batteries also offer relatively low self-discharge rates.

These batteries are known for lasting long and are also surprisingly light.

They last longer than many other types of batteries and can be counted on to last. It is important to remember that they cost more than lead-acid batteries.

Let’s find out how many lithium-ion batteries you may need to run a 5000-watt power inverter. For this example, let’s take 100Ah and 48V lithium batteries.

5000W / 48 V = 104.2 A [The current it will draw]

100Ah x 1C = 100A [Charge & Discharge rate of 100Ah li-ion battery]

104.2A / 100A = 1.04 ≈ 1 Battery

Battery Configuration

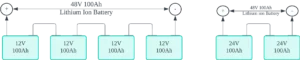

You can use a 48V 100Ah server rack. However, you can also use several wired batteries, like four 12V 100Ah batteries in series.

Two 24V 100Ah batteries in the series will also work for this example.

Similarly, if you use another Ah battery, you can do the same calculations to find the number of batteries.

We have made that more manageable for you in the following table.

| Battery Capacity | C-rate | Charge and discharge rate | Number of batteries for 5000 W inverter |

| Li-ion 40Ah | 1C | 40Ah x 1 C = 40A | 5000W / 48V / 40A = 2.6 ≈ 3 Batteries |

| Li-ion 70Ah | 1C | 70Ah x 1 C = 70A | 5000W / 48V / 70A = 1.5 ≈ 2 Batteries |

| Li-ion 100Ah | 1C | 100Ah x 1 C = 100A | 5000W / 48V / 100A = 1.04≈ 1 Battery |

| Li-ion 135Ah | 1C | 135Ah x 1 C = 135A | 5000W / 48V / 135A = 0.8 ≈ 1 Battery |

| Li-ion 150Ah | 1C | 150Ah x 1 C = 150A | 5000W / 48V / 150A = 0.7 ≈ 1 Battery |

| Li-ion 200Ah | 1C | 200Ah x 1 C = 200A | 5000W / 48V / 200A = 0.5 ≈ 1 Battery |

Lead Acid Battery: How many batteries are needed for a 5000-watt inverter?

A lead acid battery is also a type of rechargeable battery.

This device uses lead electrodes and a sulfuric acid solution to make electricity. People often find these batteries in cars, backup power, and IPS systems.

Lead-acid batteries are cheap and can deliver high surge currents.

However, they have a limited lifecycle and are susceptible to sulfation if improperly maintained.

Most importantly, they don’t store a lot of energy. However, these batteries are great if you want to save money.

Let’s find out how many lead acid batteries you may need to run a 5000-watt power inverter. For this example, let’s take 200Ah and 48V lead acid batteries.

5000W / 48 V = 104.2 A [The current it will draw]

200Ah x 0.2C = 40A [Charge & Discharge rate of 200Ah lead acid battery]

104.2A / 40A = 2.6 ≈ 3 Batteries

We need three 200Ah batteries for a capacity 600Ah because 600Ah x 0.2C = 120A, which is higher than 104.2 of inverter current.

However, we need a 48V 600Ah lead-acid battery to power a 5000-watt inverter effectively.

Battery Configuration

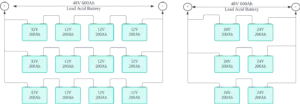

A possible battery configuration is four 12V 200Ah batteries in series and parallel with two other strings for 4S 3P batteries.

We can also use two 24V 200Ah in series and parallel with two other strings for 2S 3P batteries.

| Battery Capacity | C-rate | Charge and discharge rate | Number of batteries for 5000W inverter |

| Lead Acid 80Ah | 0.2C | 80Ah x 0.2 C = 16A | 5000W / 48V / 16A = 6.5 ≈ 7 Batteries |

| Lead Acid 100Ah | 0.2C | 100Ah x 0.2 C = 20A | 5000W / 48V / 20A = 5.2 ≈ 6 Batteries |

| Lead Acid 120Ah | 0.2C | 120Ah x 0.2 C = 24A | 5000W / 48V / 24A = 4.3 ≈ 5 Batteries |

| Lead Acid 135Ah | 0.2C | 135Ah x 0.2 C = 27A | 5000W / 48V / 27A = 3.9 ≈ 4 Batteries |

| Lead Acid 150Ah | 0.2C | 150Ah x 0.2 C = 30A | 5000W / 48V / 30A = 3.5 ≈ 4 Batteries |

| Lead Acid 200Ah | 0.2C | 200Ah x 0.2 C = 40A | 5000W / 48V / 40A = 2.60 ≈ 3 Batteries |

Expert Advice

It’s essential to consider voltage, volume, and C-rate when choosing batteries for power inverters. As you know, the C-rate for a lithium battery is 1C, and the C-rate for a lead-acid battery is 0.2C.

This means lithium cells can be charged or drained at the same rate for one hour. On the other hand, a lead-acid battery can be charged or drained at a rate of one-fifth of its capacity every hour.

- Always charge batteries before connecting them.

- You need a 48V 100Ah battery for lithium batteries for a 5000-watt power inverter.

- You need a 48V 600Ah battery for a lead-acid battery for a 5000W power inverter.

- Always respect the C-rate of a battery

Get in touch with us right away to talk about your battery needs and find the best power inverter for you. Reach out now to power your projects with confidence.